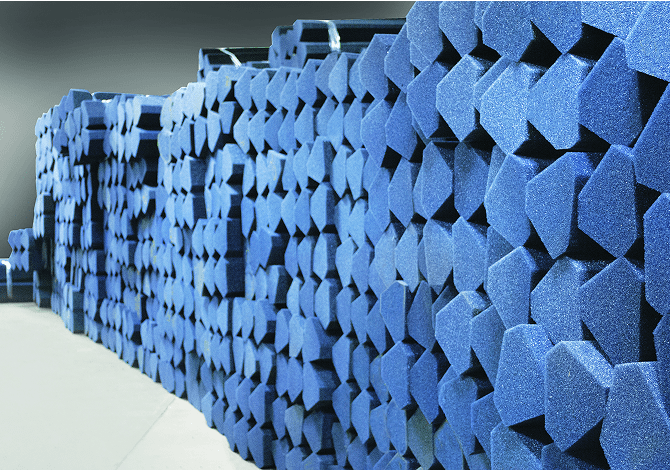

Containment Berm Foams

Our containment berm foams are physical barriers designed to contain spills and leaks in oil and gas drilling environments.

These foams are mainly used to support well site liners for portable containment vessels called duck ponds.

Containment berm foams are enclosed by plastic liners, which are situated between the hazardous liquids stored in the ponds and the concrete, swimming pool-like perimeters of the ponds.

Containment berm foams maintain their shape in cold weather and are engineered to withstand repeated compression for primary and secondary spill containment.

As with all Bergad Specialty Foam products, we offer industry standard sizes to meet the specific needs of your project.

Sizes Include:

- Isosceles Triangles (2 sides of equal length): 4”, 8”, and 12”

- Squares: 4”x4”, 8”x8”, and 12”x12”

The three types of containment berm foam we offer are:

- Hurricane Foam – Conventional open-cell foam with a density of 1.5 lbs./ft3

- Traditional Foam – Reticulated open-cell foam

- XLPE Foam – Cross-linked polyethylene closed-cell foam available exclusively in 8” triangles

Our most popular containment berm foam is Hurricane Foam in 8” triangles. This foam offers a cost-effective solution without sacrificing performance.

Key Features

Square, triangle, or custom profile options

- Do not retain water

- Chemical-resistant

- Cost efficient

- Capable of sustaining the weight of vehicles & equipment without compromising containment properties

We stock 5,000–10,000 linear feet of containment berm foam. This deep inventory allows us to ship within 1–2 days (or 5–6 days in extreme cases) compared to the 3–4 week lead times typical for other foam providers.